产品介绍

一、结构特点

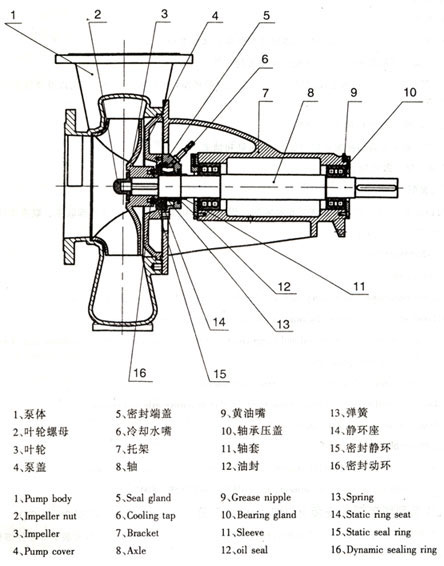

YMTL系列脱硫泵是我公司引进消化国外先进技术,结合国内实际需要研制而成的单级单吸夹板组合式离心泵,是电厂或各类企业用于烟气脱硫环保达标的一种理想的专用设备。

该脱硫泵的所有过流部件全部采用强度高,耐磨耐腐(抗氯离子)性能好的非金属材料,经高温高压一次性模压成型,外壳采用抗压、抗冲击的优质A3钢经熔模铸造而成,机械密封选用耐磨耐腐性能极佳的特级无压烧结碳化硅精制而成,整个密封箱结构设计独特,科学合理,同类产品无可比拟,密封效果好,使用寿命一般是同类产品的3-5倍。

该泵广泛适用于温度在120度以下,含固量(硬质软质颗粒不限)不超过40%的任意浓度的酸、碱、盐(含氯离子介质)强氧化剂、有机溶剂等介质的输送。特别适用于电厂烟气脱硫和污水处理使用,完全可以替代进口产品。

发明专利:200610038664.2

发明专利:200610038664.2

实用专利:200620069900.2

外观专利:200630081174.1

(注:我公司同时也生产材质为双相不锈钢的脱硫专用 泵:TLB系列脱硫泵 )

二、型号意义

| 泵型号 model |

流量 capacity m3/h |

扬程 head m |

效率 efficiency % |

必需汽蚀余量 NPSHr m |

配用功率 motor power KW |

额定转速 revolutional speed r/min |

| TLB25-25-125 | 3.2 | 20 | 53 | 2 | 1.1 | 2900 |

| 1.6 | 5 | 45 | 2 | 0.55 | 1450 | |

| TLB25-25-160 | 3.2 | 32 | 46 | 2 | 2.2 | 2900 |

| 1.6 | 8 | 40 | 2 | 0.55 | 1450 | |

| TLB25-25-200 | 3.2 | 50 | 38 | 2 | 4 | 2900 |

| 1.6 | 12.5 | 33 | 2 | 0.75 | 1450 | |

| TLB25-25-250 | 3.2 | 80 | 33 | 2 | 5.5 | 2900 |

| 1.6 | 20 | 27 | 2 | 1.5 | 1450 | |

| TLB40-32-125 | 6.3 | 20 | 52 | 2 | 2.2 | 2900 |

| 3.2 | 5 | 46 | 2 | 0.55 | 1450 | |

| TLB40-32-160 | 6.3 | 32 | 47 | 2 | 3 | 2900 |

| 3.2 | 8 | 42 | 2 | 0.75 | 1450 | |

| TLB40-32-200 | 6.3 | 50 | 38 | 2 | 5.5 | 2900 |

| 3.2 | 12.5 | 38 | 2 | 0.75 | 1450 | |

| TLB40-32-250 | 6.3 | 80 | 32 | 2 | 7.5 | 2900 |

| 3.2 | 20 | 35 | 2 | 1.5 | 1450 | |

| TLB50-32-125 | 12.5 | 20 | 51 | 2 | 3 | 2900 |

| 6.3 | 5 | 45 | 2 | 0.55 | 1450 | |

| TLB50-32-160 | 12.5 | 32 | 46 | 2 | 4 | 2900 |

| 6.3 | 8 | 40 | 2 | 0.75 | 1450 | |

| TLB50-32-200 | 12.5 | 50 | 39 | 2 | 7.5 | 2900 |

| 6.3 | 12.5 | 33 | 2 | 1.1 | 1450 | |

| TLB50-32-250 | 12.5 | 80 | 33 | 2 | 15 | 2900 |

| 6.3 | 20 | 27 | 2 | 2.2 | 1450 | |

| TLB65-50-125 | 25 | 20 | 62 | 2 | 3 | 2900 |

| 12.5 | 5 | 55 | 2 | 0.55 | 1450 | |

| TLB65-50-160 | 25 | 32 | 57 | 2 | 5.5 | 2900 |

| 12.5 | 8 | 51 | 2 | 1.1 | 1450 | |

| TLB65-40-200 | 25 | 50 | 52 | 2 | 11 | 2900 |

| 12.5 | 12.5 | 46 | 2 | 1.5 | 1450 | |

| TLB65-40-250 | 25 | 80 | 46 | 2 | 18.5 | 2900 |

| 12.5 | 20 | 39 | 2 | 3 | 1450 | |

| TLB65-40-315 | 25 | 125 | 39 | 2 | 30 | 2900 |

| 12.5 | 32 | 33 | 2 | 5.5 | 1450 | |

| TLB80-65-125 | 50 | 20 | 69 | 2 | 5.5 | 2900 |

| 25 | 5 | 64 | 2 | 1.1 | 1450 | |

| TLB80-65-160 | 50 | 32 | 67 | 2 | 11 | 2900 |

| 25 | 8 | 62 | 2 | 1.5 | 1450 |

| 泵型号 model |

流量 capacity m3/h |

扬程 head m |

效率 efficiency % |

必需汽蚀余量 NPSHr m |

配用功率 motor power KW |

额定转速 revolutional speed r/min |

| TLB80-50-200 | 50 | 50 | 63 | 2 | 15 | 2900 |

| 25 | 12.5 | 57 | 2 | 2.2 | 1450 | |

| TLB80-50-250 | 50 | 80 | 57 | 2 | 30 | 2900 |

| 25 | 20 | 53 | 2 | 4 | 1450 | |

| TLB80-50-315 | 50 | 125 | 48 | 2 | 45 | 2900 |

| 25 | 32 | 43 | 2 | 7.5 | 1450 | |

| TLB100-80-125 | 100 | 20 | 77 | 4.3 | 11 | 2900 |

| 50 | 5 | 73 | 3 | 1.5 | 1450 | |

| TLB100-80-160 | 100 | 32 | 73 | 4.3 | 15 | 2900 |

| 50 | 8 | 72 | 3 | 3 | 1450 | |

| TLB100-65-200 | 100 | 50 | 72 | 4.3 | 30 | 2900 |

| 50 | 12.5 | 68 | 3 | 4 | 1450 | |

| TLB100-65-250 | 100 | 80 | 68 | 4.3 | 55 | 2900 |

| 50 | 20 | 65 | 3 | 5.5 | 1450 | |

| TLB100-65-315 | 50 | 32 | 58 | 3 | 11 | 1450 |

| TLB125-100-200 | 200 | 50 | 77 | 4.3 | 45 | 2900 |

| 100 | 12.5 | 72 | 3 | 7.5 | 1450 | |

| 67 | 6 | 71 | 2.5 | 4 | 980 | |

| TLB125-100-250 | 200 | 80 | 75 | 4.3 | 75 | 2900 |

| 100 | 20 | 72 | 2.3 | 11 | 1450 | |

| 67 | 9 | 71 | 2.5 | 5.5 | 980 | |

| TLB125-100-315 | 100 | 32 | 68 | 2.5 | 18.5 | 1450 |

| 67 | 15 | 67 | 2.5 | 7.5 | 980 | |

| TLB125-100-400 | 100 | 50 | 60 | 2.5 | 30 | 1450 |

| 67 | 23 | 59 | 2.5 | 11 | 980 | |

| TLB150-125-250 | 200 | 20 | 77 | 2.8 | 18.5 | 1450 |

| 135 | 9 | 76 | 2.5 | 7.5 | 980 | |

| TLB150-125-315 | 200 | 32 | 75 | 2.8 | 30 | 1450 |

| 135 | 15 | 74 | 2.5 | 11 | 980 | |

| TLB150-125-400 | 200 | 50 | 70 | 2.5 | 45 | 1450 |

| 135 | 23 | 69 | 2.5 | 18.5 | 980 | |

| TLB200-150-250 | 400 | 20 | 81 | 4 | 37 | 1450 |

| 270 | 10 | 80 | 2.8 | 11 | 980 | |

| TLB200-150-315 | 400 | 32 | 79 | 3.5 | 55 | 1450 |

| 270 | 15 | 79 | 2.8 | 18.5 | 980 | |

| TLB200-150-400 | 400 | 50 | 78 | 3.5 | 90 | 1450 |

| 270 | 23 | 78 | 2.8 | 30 | 980 | |

| TLB200-150-500 | 400 | 80 | 75 | 3.5 | 160 | 1450 |

| 270 | 36 | 75 | 2.8 | 55 | 980 |

| 泵型号 model |

流量 capacity m3/h |

扬程 head m |

效率 efficiency % |

必需汽蚀余量 NPSHr m |

配用功率 motor power KW |

额定转速 revolutional speed r/min |

| TLB250-200-400 | 400 | 20 | 82 | 3 | 45 | 980 |

| 306 | 12 | 81 | 2.8 | 30 | 750 | |

| 600 | 40 | 85 | 3.5 | 132 | 1450 | |

| TLB250-200-500 | 400 | 32 | 79 | 3 | 75 | 980 |

| 306 | 18 | 78 | 2.8 | 37 | 750 | |

| 600 | 70 | 84 | 3.5 | 160 | 1450 | |

| TLB250-200-600 | 400 | 50 | 75 | 3 | 110 | 980 |

| 306 | 29 | 74 | 2.8 | 55 | 750 | |

| 600 | 100 | 80 | 3.5 | 315 | 1450 | |

| TLB300-250-400 | 800 | 20 | 83 | 3.5 | 90 | 980 |

| 610 | 12 | 82 | 3 | 45 | 750 | |

| 480 | 7 | 80 | 3 | 22 | 590 | |

| 1200 | 40 | 85 | 3.8 | 280 | 1450 | |

| TLB300-250-500 | 800 | 32 | 82 | 3.5 | 132 | 980 |

| 610 | 18 | 81 | 3 | 55 | 750 | |

| 480 | 11 | 79 | 3 | 30 | 590 | |

| 1200 | 70 | 83 | 3.8 | 315 | 1450 | |

| TLB300-250-600 | 800 | 50 | 79 | 3.5 | 200 | 980 |

| 610 | 29 | 78 | 3 | 90 | 750 | |

| 480 | 18 | 76 | 3 | 45 | 590 | |

| TLB350-300-450 | 1500 | 20 | 86 | 3.5 | 132 | 980 |

| 1140 | 12 | 85 | 3 | 75 | 750 | |

| 900 | 7 | 84 | 3 | 37 | 590 | |

| TLB350-300-550 | 1500 | 32 | 85 | 3.5 | 200 | 980 |

| 1140 | 18 | 84 | 3 | 110 | 750 | |

| 900 | 11 | 83 | 3 | 55 | 590 | |

| TLB350-300-650 | 1500 | 50 | 83 | 3.5 | 315 | 980 |

| 1140 | 29 | 82 | 3 | 160 | 750 | |

| 900 | 18 | 81 | 3 | 75 | 590 | |

| TLB400-350-450 | 2000 | 20 | 87 | 3.5 | 200 | 980 |

| 1500 | 12 | 86 | 3 | 110 | 750 | |

| 1200 | 8 | 85 | 3 | 45 | 590 | |

| TLB400-350-550 | 2000 | 32 | 86 | 3.5 | 280 | 980 |

| 1500 | 19 | 85 | 3 | 132 | 750 | |

| 1200 | 12 | 84 | 3 | 55 | 590 | |

| TLB400-350-650 | 2000 | 50 | 87 | 4 | 450 | 750 |

| 1500 | 32 | 86 | 3.8 | 200 | 590 | |

| 1300 | 20 | 85 | 3.8 | 132 | 500 | |

| TLB450-400-500 | 2500 | 20 | 87 | 4 | 250 | 980 |

| 1900 | 12 | 86 | 3.8 | 110 | 750 | |

| 1500 | 8 | 85 | 3.8 | 55 | 590 | |

| TLB450-400-600 | 2500 | 32 | 88 | 4 | 355 | 980 |

| 1900 | 19 | 87 | 3.8 | 160 | 750 | |

| 1500 | 12 | 86 | 3.8 | 110 | 590 | |

| TLB450-400-700 | 2500 | 50 | 87 | 4 | 560 | 750 |

| 2000 | 32 | 86 | 3.8 | 280 | 590 | |

| 1700 | 20 | 85 | 3.8 | 160 | 500 | |

| TLB500-450-600 | 3000 | 20 | 88 | 4 | 250 | 750 |

| 2360 | 12 | 87 | 3.8 | 132 | 590 | |

| 2000 | 8 | 86 | 3 | 75 | 500 | |

| TLB500-450-700 | 3000 | 32 | 87 | 4 | 400 | 750 |

| 2360 | 20 | 86 | 3.8 | 250 | 590 | |

| 2000 | 14 | 85 | 2 | 132 | 500 | |

| TLB500-450-800 | 3000 | 50 | 85 | 4 | 630 | 750 |

| 2360 | 30 | 84 | 3.8 | 315 | 590 | |

| 2000 | 21 | 83 | 3 | 200 | 500 |

上一篇:700DT-A84脱硫泵

下一篇:TLB系列脱硫泵